Troubleshooting 2008 Ford Explorer PCM Problems

The Powertrain Control Module (PCM) in a 2008 Ford Explorer serves as the brain of the vehicle’s engine and transmission systems. This sophisticated electronic control unit is responsible for monitoring and managing various engine parameters, ensuring optimal performance, fuel efficiency, and emissions control. The PCM processes data from numerous sensors located throughout the vehicle, including the mass airflow sensor, throttle position sensor, and oxygen sensors.

By interpreting this data, the PCM can make real-time adjustments to fuel injection, ignition timing, and other critical functions to maintain the engine’s performance under varying conditions. In addition to its role in engine management, the PCM also communicates with other onboard systems, such as the anti-lock braking system (ABS) and the transmission control module (TCM). This interconnectedness means that any issues with the PCM can have far-reaching effects on the vehicle’s overall functionality.

For instance, if the PCM fails to receive accurate data from a sensor, it may trigger warning lights on the dashboard or lead to erratic engine behavior. Understanding the PCM’s role is crucial for diagnosing and addressing potential issues that may arise in a 2008 Ford Explorer.

Key Takeaways

- The PCM in a 2008 Ford Explorer is a crucial component that controls various functions of the vehicle’s engine and transmission.

- Common symptoms of PCM problems in a 2008 Ford Explorer include engine stalling, rough idling, and difficulty starting the vehicle.

- Diagnostic tools such as OBD-II scanners and multimeters can be used to troubleshoot PCM problems in a 2008 Ford Explorer.

- Steps for checking and testing the PCM in a 2008 Ford Explorer include inspecting for visible damage, checking for error codes, and performing voltage tests.

- Addressing wiring and connection issues related to the PCM in a 2008 Ford Explorer is essential for ensuring proper functionality of the vehicle.

Common Symptoms of PCM Problems in a 2008 Ford Explorer

When the PCM in a 2008 Ford Explorer begins to malfunction, several symptoms may manifest, indicating that something is amiss. One of the most common signs of PCM problems is poor engine performance. Drivers may notice a decrease in acceleration, rough idling, or stalling while driving.

These symptoms often stem from incorrect fuel-air mixture adjustments or timing issues that the PCM is unable to manage effectively. In some cases, the vehicle may also experience difficulty starting, which can be attributed to the PCM’s failure to send the appropriate signals to the fuel injectors or ignition system. Another prevalent symptom of PCM issues is the illumination of warning lights on the dashboard.

The check engine light is particularly notorious for signaling problems related to the PCM. When this light activates, it indicates that the PCM has detected an anomaly within the engine management system. Additionally, other warning lights may also appear, such as those for the ABS or traction control systems, further complicating the diagnosis.

Drivers should be vigilant about these warning signs, as they can lead to more severe mechanical failures if left unaddressed.

Diagnostic Tools and Techniques for Troubleshooting PCM Problems

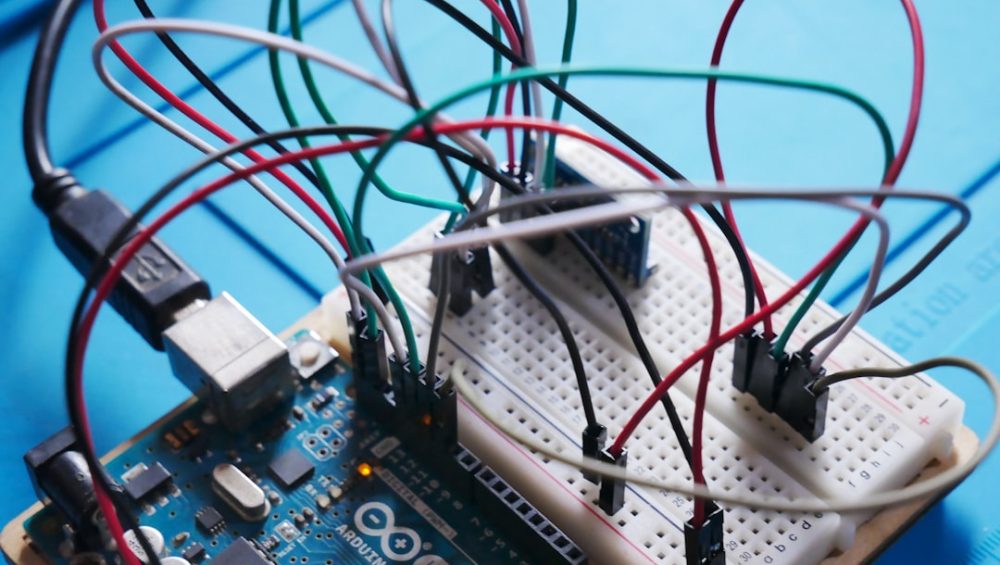

To effectively troubleshoot PCM problems in a 2008 Ford Explorer, a variety of diagnostic tools and techniques can be employed. One of the most essential tools is an OBD-II (On-Board Diagnostics II) scanner. This device connects to the vehicle’s diagnostic port and retrieves trouble codes stored in the PCM’s memory.

These codes provide valuable insights into specific issues affecting the engine and other systems. For instance, a code indicating a malfunctioning oxygen sensor can help pinpoint a problem that may be affecting fuel efficiency and emissions. In addition to OBD-II scanners, multimeters and oscilloscopes can be utilized to test electrical signals and sensor outputs.

A multimeter can measure voltage levels at various points in the wiring harness connected to the PCM, helping to identify any shorts or open circuits that may be causing communication failures. Oscilloscopes can provide a visual representation of signal waveforms, allowing technicians to analyze sensor performance over time. By combining these diagnostic tools with a systematic approach to troubleshooting, mechanics can accurately identify and address PCM-related issues in a 2008 Ford Explorer.

Steps for Checking and Testing the PCM in a 2008 Ford Explorer

| Step | Description |

|---|---|

| 1 | Locate the PCM in the engine compartment |

| 2 | Inspect the PCM for any physical damage or corrosion |

| 3 | Check the wiring harness and connectors for any signs of damage or loose connections |

| 4 | Use a diagnostic scanner to check for any trouble codes stored in the PCM |

| 5 | Perform a functional test of the PCM using the diagnostic scanner |

| 6 | Check the power and ground connections to the PCM |

| 7 | Verify that the PCM is receiving the proper voltage and signals from other sensors |

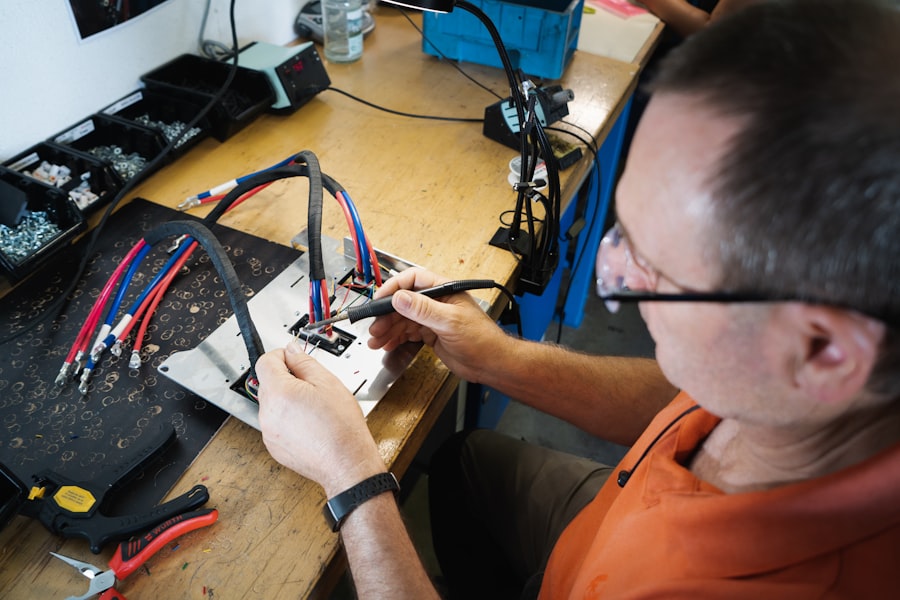

When checking and testing the PCM in a 2008 Ford Explorer, it is essential to follow a structured process to ensure thorough diagnostics. The first step involves visually inspecting the PCM and its associated wiring harness for any signs of damage or corrosion. This includes checking for frayed wires, loose connections, or moisture intrusion that could compromise electrical integrity.

A clean and secure connection is vital for proper communication between the PCM and other vehicle systems. Once visual inspections are complete, technicians should proceed with using an OBD-II scanner to retrieve any stored trouble codes. These codes will guide further testing by indicating which sensors or systems may be malfunctioning.

After identifying potential issues based on trouble codes, it is crucial to test individual sensors and components for proper operation. This may involve using a multimeter to measure voltage outputs or resistance levels at specific connectors. If any sensors are found to be faulty, they should be replaced before retesting the PCM’s functionality.

Addressing Wiring and Connection Issues Related to the PCM

Wiring and connection issues are often at the root of many PCM-related problems in a 2008 Ford Explorer. Over time, exposure to heat, moisture, and road debris can lead to deterioration of wiring insulation and connectors. To address these issues effectively, technicians should begin by performing a comprehensive inspection of all wiring associated with the PCM.

This includes checking for signs of wear or damage along the entire length of wiring harnesses leading to and from the module. If any damaged wires or connectors are identified during inspection, they must be repaired or replaced promptly. In some cases, simply re-securing loose connections can resolve communication issues between the PCM and other components.

Additionally, applying dielectric grease to connectors can help prevent moisture intrusion and corrosion over time. Ensuring that all connections are clean and secure is critical for maintaining reliable communication between the PCM and various sensors throughout the vehicle.

Potential Solutions for Resolving PCM Problems in a 2008 Ford Explorer

Resolving PCM problems in a 2008 Ford Explorer may involve several potential solutions depending on the nature of the issue identified during diagnostics. If trouble codes indicate that specific sensors are malfunctioning, replacing those sensors is often the most straightforward solution. For example, if an oxygen sensor is found to be faulty, replacing it can restore proper fuel management and improve engine performance.

In cases where wiring issues are detected, repairing or replacing damaged wires and connectors can significantly enhance communication between the PCM and other systems. If these solutions do not resolve the problem, reprogramming or updating the PCM’s software may be necessary. Manufacturers periodically release software updates that address known issues or improve performance; thus, ensuring that the PCM is running on the latest software version can sometimes rectify persistent problems.

In more severe cases where physical damage has occurred to the PCM itself—such as from water intrusion or impact—replacement of the module may be required. This process involves removing the old unit and installing a new or refurbished one while ensuring that all connections are secure and properly configured.

Preventative Maintenance for the PCM in a 2008 Ford Explorer

Preventative maintenance plays a crucial role in prolonging the life of the PCM in a 2008 Ford Explorer and minimizing potential issues down the line. Regularly scheduled maintenance checks should include inspections of all electrical connections related to the PCM. Keeping connectors clean and free from corrosion can prevent many common problems associated with poor electrical contact.

Additionally, ensuring that all vehicle sensors are functioning correctly is vital for maintaining optimal communication with the PCM. Regularly replacing worn-out sensors—such as oxygen sensors or mass airflow sensors—can help prevent erroneous readings that may lead to improper engine management decisions by the PCM. Furthermore, routine oil changes and fluid checks contribute to overall engine health, indirectly supporting proper PCM function by ensuring that all systems operate within their designed parameters.

Another important aspect of preventative maintenance involves monitoring for any warning lights on the dashboard. Addressing these alerts promptly can prevent minor issues from escalating into more significant problems that could affect the PCM’s performance.

Seeking Professional Help for Persistent PCM Issues in a 2008 Ford Explorer

While many DIY enthusiasts may feel confident tackling basic diagnostics and repairs related to PCM issues in their 2008 Ford Explorer, there are instances where professional assistance becomes necessary. If troubleshooting efforts do not yield clear results or if multiple components appear to be malfunctioning simultaneously, seeking help from an experienced automotive technician is advisable. Professionals possess specialized knowledge and access to advanced diagnostic equipment that can provide deeper insights into complex electrical issues.

Moreover, if there are indications of internal damage within the PCM itself—such as erratic behavior despite proper sensor readings—consulting with a professional is essential. They can perform more sophisticated tests and determine whether reprogramming or replacement of the module is warranted. In some cases, technicians may also have access to manufacturer-specific tools that allow them to perform tasks beyond standard OBD-II diagnostics.

Ultimately, while many aspects of diagnosing and resolving PCM problems can be managed independently by vehicle owners, recognizing when professional expertise is required can save time and prevent further complications down the road.

If you are experiencing PCM problems with your 2008 Ford Explorer, you may also be interested in reading about how to diagnose a bad ECM. This article from Module Mechanics provides helpful tips and information on identifying issues with your vehicle’s Engine Control Module. By understanding the symptoms and potential causes of ECM problems, you can better address any issues affecting your Ford Explorer’s performance. Check out the article here for more details.